THE INHERITANCE OF A TURKISH BOWYER

A Document from the Ottoman Archive

Şinasi Acar & Dr. Murat Özveri

This article is about a document we found in the Ottoman Archive of Turkish Republic Prime Ministery. It is listed under 23/96 and 23/97 in Kısmeti- Askeriyye Mahkemesi and in fact a court report about the inheritage of Yusuf Beşeand reveals important information about the Turkish traditional archery and bowyery, i.e. the tools that a bowyer of this time era was using, what type of bows were manufactured and what all these material costed. The text of this document is dated back to 31/10/1705 and is as follows:

“Yusuf Beşe the bowyer, son of Abdullah, who was a soldier of the 29th Troop of Janissaries and staying in Hatice Sultan District in Üsküdar, deceased a while ago. …Since he has no inheritors other than his wife Hatice hanım – daughter of Mustafa-one fourth of his inheritage shall belong to her and three fourth of it shall be taken by the state. His inheritage can be found below…

This kind of records are quite rare and was made only if there was a conflict between the inheritors. Appearantly Yusuf Beşe had a seperated wife but no children. Because it is well-known that Yeniçeri (Janissaries) were not allowed to marry, it makes sense to believe that he got married after his retirement. The court might have involved because of the requests of payees who were also mentioned in the document. It is obvious that the sale of the inherited bows and other material would pay out Yusuf’s debts.

Who is Yusuf Beşe?

Yusuf Beşe was a bowyer and also a Yeniçeri soldier. Yeniçeri were foot soldiers of the Ottoman army. The very early establishment of Yeniçeri troops were thought to have gone back to 14th century. Ancient Turkish armies were mainly based on mounted archers who fought with the typical “attack-and-retreat” strategy of Central Asian warfare. Turks opened the gates of Anatolia with the Manzikert battle in 1071. Seldjuk Sultanate was followed by Ottomans. Becoming a more developed state just a few decades after its foundation and starting the conquests arose the need for foot soldiers.

For more than three centuries the despotism of Ottoman dynasty was based almost exclusively upon a deliberate policy of government by a slave class. This method of government seems to have been developed by the Turkish rulers as a defensive mechanism designed to exclude native-born subjects from the government, to eliminate the rise of aristocracy of blood or of a hereditary official class.

It must be remembered in considering this system of the constitution of the army and the government of the state by a slave class that slavery in Muslim lands was too much different than that in Europe and often proved the most direct road to fortune and honour. The teaching of the Prophet that slaves should be treated with kindness and generocity, that they should be fed and clothed in the same manner as the members of the master’s own familiy, in Muslim East slavery has never had the meaning that was attached to it in West. As an example, the Georgians and Circassians who found the slave trade with Constantinople so profitable and maintained slave farms to meet the demand, reared their own children, because they were considering the Palace service the best possible opening for a brilliant carrier.

Slaves were supplied through capture, purchase, gift and the Law of Tribute Children or the Law of Draft (the system of Devşirme). This law was about drafting the recruits for the army from the conquered European provinces. The law denied to the people of these provinces the usual right accorded Christians of payment of the capitation tax in lieu of military service, and instead exacted as tribute a stipulated number of male children every three or four years. The second important source of supply was prisoners of war. The most physically perfect, the most intelligent, and the most promising in every respect were set aside for the Palace service. They were educated in the Palace School called “Enderûn-u Humayûn” and graduated as high rank officers, burocrates or the members of Cavalry of Sublime Porte, the elite soldiers of the Sultan. The remainder who were distinguished mainly because of their physical strength and dexterity were asigned to the Yeniçeri corps.

A part of the education in the Palace School was learning “some art and occupation according to the capacity of their spirit”. All Turks were formerly accustomed to learn some art or science, by means of which he could earn a livelihood in case he should fall upon evil days. Sultans were no exception and many of them excelled in their choosen craft. The only exception was the Yeniçeri (Janissaries). Unlike the “iç oğlanları” who were educated in the Palace, the pages of Yeniçeri Corps were only trained for becoming efficient soldiers

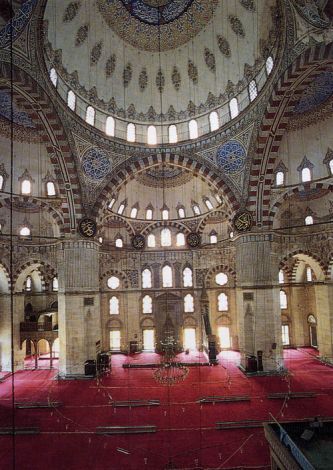

However, there was an exception of it too. A few of the Janissary troops, the so-called Aga Bölükleri, consisted of craftsmen to provided the needed weaponry and tools for the army. We believe that Yusuf Beşe was one of the bowyers educated in these troops. Their workshops were in Süleymaniye district in İstanbul and their salaries were carefully recorded in the Ehl-i Hiref Defterleri, the account boos of craftsmen’s organization for the palace, that remained till today.

Our attempt in finding his name among the 18th century bowyers failed, but surprisingly, we were able to find Yusuf Beshe’s name in the list of the kemankeş (licenced archers). His 908 gez (599 m) flight shot was recorded and a monumental “menzil stone” was erected in the memory of this shot. Not only his name but also his professional position, mirâhur were mentioned, so there is no doubt about his identitiy. There are other records about bowyers who were also renowned archers of their time.

Mirâhur means “the director of the stables of Sultan” and was an important position in the palace. Mirâhur was one of the members of “bîrun erkânı”, the employees who were allowed to overnight out of the Palace. His title “beşe”, a higher rank among janissaries also proves that he was not an ordinary Janissary soldier.

Turkish Bowyery and the Composite Bow

Bowyery was a significant sector in Otoman Empire. Bows were manufactured in both civillian and official workshops. Flight shooting which is the less war-related archery discipline gained popularity after the 17th century, but enthusiasts kept performing target archery in ok meydanları (archery fields) or tâlimhâneler (indoor shooting ranges). Long after the army switched to firarms the bow production in Istanbul was supported by this civillian demand.

Ottoman master bowyers refined and developed the Asian style composite bow to unprecedented and yet unsurpassed levels.

Turks have their roots in Central Asia where hard climate and challenging circumstances made people of various ethnic origins develop a special type of nomadism. In this life style riding and shooting the bow have become a part of daily life. Central Asian nomads were brought up to become perfect riders as well as amazing archers as a result of training that started in early stages of their lives. The need to shorter and stronger bows that enable the archer to shoot on horseback arose as the natural outcome of this life style. Since all-wooden bow designs would not have fulfilled the demand to shorter bows, composite bow technology was developed.

The Central Asian nomadic culture not only developed this technology but also created new bow designs based on the advantages brought by combining the four materials. The so-called reflex and recurve profiles allowed the bow store more energy at the same draw weight and draw length. All these spesifications made these bows very powerful and long-ranged.

Picture 1: One of the most important features that differs Turkish bows from straight limbed western bows is the recurved limb design. (Photograph: Fuat Özveri).

The rationale of the composite bow is combining several materials to achieve the most convenient mechanical properties a bow can have. There is a wood core or a kind of skeleton that consists the profile of the bow and serves as a gluing surface for sinew and horn. The back of the bow that faces tensile forces during function is covered with sinew, a material which is more resistant than wood to that type of stress. The belly side is under compression during draw, and on this surface, horn gives support to the wood core. All these materials are glued to each other by using collagen-based glues derived from animal tissues.

The Bows and Bowyery-Related Items in the Document

The bowyery-related items found in Yusuf Beşe’s workshop are as shown below:

|

ITEM

|

AMOUNT

|

PRICE (akçe)

|

ITEM

|

AMOUNT

|

PRICE (akçe)

|

|

Tartar bow

|

95 pieces

|

7695

|

Tondj

|

“some amount of

|

45

|

|

Egyptian bow

|

15 pieces

|

200

|

Bow stave

|

15 pair

|

45

|

|

Sinew

|

377 pairs

|

761

|

|

|

|

|

Fish glue

|

12 kıyye (15,4 kg)

|

360

|

Tepelik kemend and sinew comb

|

Not mentioned

|

160

|

|

Horn for bows

|

30 pieces

|

660

|

Thick rope

(URGAN)

|

8 pieces

|

46

|

|

Pounded fish glue

|

not mentioned

|

61

|

Bow remains

|

Not mentioned

|

42

|

|

Dark glue

|

30 dirhem 6 kıyye (7,8 kg)

|

219

|

Glue pot

|

1

|

120

|

|

Horn remains

|

not mentioned

|

20

|

Striped scale (kayış kantarı??)

|

1

|

42

|

While we get through the items on the table, we will summerize how to make a Turkish composite bow.

The first step was shaping the wood pieces that will form the wooden skeleton. This substructure was built by bringing the grip and limbs together. The limbs were recurved prior to gluing to the grip section. It was followed by gluing the horn strips to the belly surface. Horns of water buffalo were mostly preferred and a pair harvested from the same animal was used on one bow.

“Horn for bow” were listed as “30 pieces” that were supposed to be 15 pairs of full size horns or horn strips. The given amount of “bow staves” (15 pair) corresponds the horn amount in the stock. Obviously, the bowyer prepared the raw material for his next 15 bows just before he died. Because of the necessity of using horn strips from the same animal on one bow, Yusuf Beşe probably stored the horns in pairs, although it was not mentioned in the list.

“Horn remains” should be the wasted horn pieces after cutting and shaping the required form of horn strips. In fact, the sawed strips are only a small part of the full size horn. “Mehmed Agha, son of Ramazan”, the expert who was in charge of estimating the values of the inherited items set a price of 20 akçe for these remains. This material was supposed to be used in making knife grips, thumbrings, etc.

Binding the horn strips to the wood surface was quite important since both materials had to react like one single material under the compressive forces of function. For the purpose of increasing the glue surface, both the surfaces of strips and wood core were scratched for perfectly paralell grooves by using a comb-like metal tool, “taşin”.

Pictures 2 and 3: The taşin (tash-in) grooves help increasing the glue surface for a strong binding of two materials (Bow: S. Cem Dönmez, Photograph: Fuat Özveri).

Wooden skeleton and horn strips were pressed together and wrapped firmly. One of the weaknesses of organic glues is the long drying time in which these two materials had to be hold together. A thick rope was used to wrap around and a wooden tool called “tencek” provided the mechanical support to apply sufficient and uniform pressure during the wrapping procedure. The “thick rope” in the list was undoubltly used for this purpose. No other stage of bowmaking requires such a thick rope.

The next stage is backing the bow with sinew harvested from the leg tendons of oxes. The sinew was pounded into fibres and the fibres are seperated with a comb called “sinir tarağı”(sinew comb). Sinew comb is listed together with “tepelik kemend”.Aswill be mentioned below tepelik is the wooden form used in the tillering of the bow. Kemend is a cord, probably like a long band –as it’s seen on one of the rare old photographs- used to bind these wooden forms to the bow limbs. However it is known that “kemend” is a synonyme for “bowstringer” and the possibility of a particular type of stringer must not be completely ignored.

Picture 4: Weighing the sinew preliminary is important. The prescribed amount of sinew and glue must be combined for the best possible results (Bow and photograph by S. Cem Dönmez).

Sinew backing is applying the sinew fibres to the back of the bow after they are soaked to collagen-based hot glue. Turkish bows usually have two layers of sinew on their back. Drying of the glue is significantly influenced by the environemental moisture and may vary severely. In the first few weeks the bow takes a rounded shape due to the shrinkage of the sinew. This process which will end up with the famous reflex of Turkish bow is guided by the bowyer by tying the nock ends to the grip. The rounded bow dummy is called yay halkası, which roughly means “bow circle”.

Picture 5: A “yay halkası” in the collection of Topkapı Palace Museum-Istanbul (Photograph: Adam Karpowicz).

The bowyers in Istanbul were seasoning the yay halkası for one year before starting with tillering. After this waiting period the bow circle were straightened and strung. During this process which may have lasted weeks the bows were carefully heat treated. Two main tools were used in tillering: tepelik and asâ gezi (tillering stick). Tepelik is a flat, wooden form with one side straight and the other side convex, used to give the intended profile to the limbs. It helps to bend the limbs gradually, without applying excessive forces. Tillering stick is very similar to that of used in western bowmaking: a stick with slots to accomodate the string of the bow which is put horizontally on top of it. The bowyer draws the string step by step and adjust the bending of the limbs.

Picture 6: The tillering stick (asâ gezi) in the tillering process. (Bow and photograph: S. Cem Dönmez).

The string was made of raw silk. String had tonç (string loops) at its extremities, which was made seperately and bound to the string with tonç düğümü (special knots). The tonç of that amount was given as “some amount of” in the list are these loops.

Glues

As mentioned above, all gluing was made with glues derived from animal tissues. A particular type of glue was used alone or in precisely calculated combinations with another type, depending on where it was used. One of these glues was derived from animal tendons (sinew glue). Another major glue, known as fish glue, was derived from the palatal mucosa and air bladder of danube sturgeon (Acipencer guldenstaedtii). Fish glue was quite expensive because of the rareness of this fish species and the restricted amount of tissue which can be harvested from one animal. These glues were used in gluing the pieces of the wooden skeleton to each other, in gluing the horn laminate to the wood core and in sinew backing.

Fish glue can be stored both in gel/liquid form or as solid chips. Appearently, fish glue in both forms were ready in Yusuf Beşe’s workshop to use. The solid chips could have been stored for extended periods of time and in case the glue is needed the chips were heated with some water in a glue pot put in a larger pot filled with hot water. The amount of pounded fish glue is not mentioned while the ready-to-use glue weighed 12 kıyye (15,4 kg). Its estimated price is given as 360 akçe. It is known that the fish glue was imported and cost more than the sinew glue. The expensive fish glue was combined with sinew glue in prescribed combinations. Because of this reason the amount of fish glue used in making one bow is no more than 150 grams. A rough estimation reveals that the amount found in the workshop is sufficient to complete 100 bows. It must be remembered that making a composite bow was taking 1 to 3 years as a result of the long waiting times due to the drying period of natural glues. The number of bows a bowyer could make during his entire life was therefore limited.

Picture 7: Fish glue made from the air bladder of danube sturgeon (glue and photograph: S. Cem Dönmez).

Another type of glue which was listed is dark glue. Despite the fact that we haven’t known such a glue used in bowmaking it is easy to figure out what it is by examining its price. Obviously it is more expensive than the fish glue which shows that this glue was used only in small amounts in bowmaking. Asking the question “At which other stages of bowmaking were glues or glue-like materials used?” will bring the solution.

One of the weaknesses of composite bows is that the sinew on the back is highly vulnerable under the changes of temperature and moisture. It’s the birch bark or leather that is glued on the sinew surface to avoid these changes to effect the sinew backing. Leather coverage was protected by a special varnish called “sandalos revgânı”. In some rare samples varnish-like protectors were applied directly on the sinew surface too.

This information indicates that the “dark glue” might have been a dark colored, highly viscous material, probably a kind of natural resin that was applied on the sinew surface or leather cover. It makes sense that such a resin which might have been available only in small amounts in the nature and/or imported, would have been very expensive.

Bows

In this court report there are two types of bows listed: “Tartar bow” and “yây-ı Mısrî, ” or Egyptian bow; proving that Yusuf Beşe was making two main models.

In Ottoman Turks Tartar bow was the name for both crossbows and Crimean Tartar bows. Crossbows were not so popular in the Ottoman army and this “Tartar bow” was undoubtly used for Crimean Tartar bows. Crimean Tartars were the alliences of Ottomans and became the pioneers of the Ottoman army instead of Akıncılar, after 16th century. These warriors were light cavalry whose fighting techniques were based on Central-Asian style warfare. Their bows differs in some aspects than the bows identified today as Turkish bow. Tartar bows are also composites of wood, sinew, horn and glue. They’re mostly longer than the Turkish bow although shorter examples also existed. Their reflex begins just adjacent to the grip and they have the so-called “string bridges”, another spesification that differs them from Turkish bows.

Picture 8: Crimean Tartar bow differs from the Turkish bow with its string bridges, length, different unstrung profile and grip form. (Topkapı Palace Museum.)

Picture 10: The “Turkish bow” as named in foreign literature is shorter than most Crimean Tartar bows and has no string bridges. The grip is obviously more rounded on the back and the overall unstrung profile is different (Bow: S. Cem Dönmez. Photograph: Fuat Özveri).

This document about the inheritage of Yusuf Beşe confirms some previous literature reporting that Crimean Tartar bows were made in Istanbul. This document also enlightens some dark points about the authentic Turkish shooting technique. Crimean Tartar bows were drawn longer and shot naturally with longer arrows. The shorter Turkish arrows exhibited in the museums fail in explaining the longer draws described in some old reports. The fact that Crimean Tartar bows were made in the capital city supports the possibility that this type of bows were preferred and used by civil and/or military archers other than the warriors of the Crimean Kaghan.

In fact, the modern Anglo-American discrimination of Turkish-and Tartar bows is questionnable since Crimean Tartars had been a part of the Ottoman Empire and army. We believe that both bow types can be brought together under the lable “Ottoman bow”.

The other type of bow our bowyer was making is yay-ı Mısrî,which literally means Egyptian bow. Ottoman archery literature give the names of the bows of their time.For example, different type of composite bows like Ajem (İranian) bows or Arab bows are mentioned occasionally in old treatises. Ajem bow is very similar to Turkish bow except the wider limbs which supported by multiple, shorter horn strips on the belly, instead of one full laminate. Arab bow -although having the same composite structure- has no recurves and is straight-limbed when strung.

To discover the Egyptian bow of Yusuf Beşe it is necessary to go to the land called “Egypt” by Ottomans and have a closer look at the archery culture of Mamluk Sultanate. Mamluk’s school of archery is well-documented by archery treatises like Kitab fî ilm-an nüşşâb,written in Kiptchak dialect of Turkish in 14th century. This school of archery has its roots in Central Asia and probably influenced Ottoman bowyery. The book describes the wood-sinew-horn composite structure of the bow. However, more detailed research about Memluk fighting strategies and arms reveal that there were two main type of bows used by Memluks: Composite bows, called “el Fârsiyye”and selfbows called “el Arabiyye”. The mentioned “Arab bow” is not similar to the composite bows we find in Topkapi Palace Museum’s collection. Appearently, composite bow was brought to Egypt by Turkish warriors who had been adopted as slave soldiers and later got the political power. Composite bows had been used in the pharaonic times of Egypt as shown by the foundings of King Tuthankamun’s tomb and on numerous reliefs. But most probably, Arabs did not have this technology in this time frame. It is well known that Arabs had used straight-limbed wooden selfbows in pre-and early Islamic era. Prophet Mohammed’s bow, being exhibited in Topkapı Palace Museum is also a one-piece bamboo selfbow. Arab bows with similar profile and grip design which are in composite structure (as seen in the same museum’s collection) must have been made later.

After Sultan Selim I. conquered Egypt many craftsmen including bowyers and arrowsmiths were brought to Istanbul and it is known that Ottoman bowmaking have been influenced by Egyptian bowyers. The idea to make and use selfbows in Istanbul could have been the consequence of these historical events and cultural interactions.

Selfbows is undoubtly a stage in the progress of composite bow. But in Central Asia and Mesopotamia selfbows were left behind as early as 2300 BC and composite bows begun to appear. The main reason for that was the need of nomadic people to shorter bows which could be used on horseback. In the western world the use of selfbows continued until the firearms gained prominance on battlefields.

Selfbows’ reasonable cost and easier making process make them good weapons. They are inexpensive not only because additional raw materials like sinew, horn or glue are not needed but also the total working time is much more shorter than that of composite bows. A selfbow can be made in one day (of course by using an already seasoned bow stave) while a composite bow would require 1 to 3 years to complete.

“Egyptian bow” in this document is likely a sort of selfbow, “el Arabiyye” as called by the Mamluks. There is no strong evidence or records about the use of selfbows in Ottomans but it is highly possible. If ever used, there should have been two main places of use for selfbows. One of them might have been “tâlimhâne” or shooting ranges that provided service to civil archery practitioners. Archery was a beloved sport among civillians and these commercial institutions were survived by these hobby archers. They were thought to be indoor and outdoor, were very similar to today’s shooting ranges and it’s known that “longer bows” were used and shot at these places. Since the selfbows’ energy storing capacities are restricted by the physical properties of the wood they are made of, they can not be build short. If Ottoman bowyers have also made selfbows it is highly possible that these bows were preferred by tâlimhâneler due to their availability and lower cost. It is worth to mention additionally that the smoother draw characterstic of a longer bow is much more suitable to non-professional individuals.

Another possible use of selfbows would be hunting. All the records about how Ottomans have hunted is the records of the classical Turko-Mongol drive hunts of the royal family and the army. This hunting method had been used as a valuable war practice for centuries and is based on driving the game animals for days, even for weeks; cornering and circling around them on a big, open area and not letting them escape out of the circle of hunting people and dogs. Then the mounted warriors/hunters were entering the circle and killing the game with the weapons of the time, i.e. bow, sword, lance and mace. In Ottomans, hunting was a way to develop, sharpen up and maintain the fighting skills of the professional army. However, there is no record about paramilitary hunting, how civillians have hunted, especially around İstanbul, where riding was a privilage of elites and prohibited by law. Falconry and trapping were undoubtly used by people but we think that bow and arrow must have been also used, especially in hunting big game. If civillians have ever hunted with bow and arrow it was most probably selfbows which were much more cheaper than the composite bows and therefore easier to own.

Paramilitary hunting in Ottomans is an untouched issue which must be researched. But our thesis that yay-ı Mısrî is a selfbow, is supported by the prices of these two type of bows. As seen in the table, a Tartar bow cost 81 akçe while an Egyptian bow has a price of 13 akçe. It proves that the Egyptian bow was a low-cost bow and it makes sense that it is a selfbow.

In Yusuf’s workshop there seems to be no raw material other than 30 pieces of “horn for bow” and correspondend 15 pair of bow staves that were certainly prepared for making hornbows. Full size or in quarters splitted logs as a raw material for selfbows were not mentioned. The reason may be the extra space for such tree logs or full length staves. They might have been stored in somewhere alse. Another possible answer would be that Yusuf was not making but only retailing the Egyptian bows. Research on bowmaking in Egypt and in Istanbul as well as on the trade records of 17th-18th centuries would enlighten this point.

Kayış kantarı is the last archery-related (?) tool in the inheritage of Yusuf Beşe. This name indicates a weight scale but gives no clue about its form and use. But we believe that it was used to measure the draw weight of the bows -the only possible explanation of its existance in a bowyer’s workshop. However we must mention that the Ottoman bowyers classified the bows according to their physical weights rather than the draw weights. Although there seems to be no correlation betweeen a bow’s mass and the draw weight, further research is a must to accept or deny it completely.

The authors would like to specially acknowledge the invaluable support of Talip Mert, Adam Karpowicz, S. Cem Dönmez, Fuat Özveri.