TURKISH GLASS MAKING

Articles made of glass, being the products of human patience, creativity, and skill, are valuable works of art conveying down to our present day knowledge from the depths of history. Though it is quite fragile, glass does not change once it has assumed a form, and with its rather stable nature it is an interesting material which, resistant to the effects of Nature, does not deteriorate.

Equal in age nearly to that of civilisation itself, glass-making is one of the most ancient and advanced arts among the Turks. In their homeland of Central Asia, and in the other places to which they subsequently migrated or in which they settled, the Turks have intimately interested themselves with this craft. The various techniques which they found locally they developed, embellishing them with their own skills and taste, arriving at wholly new syntheses. The finds from excavations and the very few examples remaining to us are evidence of this view. Nevertheless, owing to the different names which the Turkish nation has taken in various localities at various periods, these are faced with the difficulty of being attributed to Turkish culture.

Without delving too deeply into Turkish history and in the form of a summary, the importance placed on glass-making by the Turks beginning with their arrival in Asia Minor-Anatolia as it is known today-lasting down to the present day, as well as the romance of glass-making make up the subject matter of this series of articles.

Before the Ottomans

Although tile making is a very advanced art among the Turks, the belief is quite widespread that glass-making showed little development, and that their requirements were generally met by imports from abroad. This is incorrect. It is a fact that this belief stems from the insufficiency of information obtained concerning glass-making among the Anatolian Seljuks and among the later Ottomans. In addition to this, the tendency of the countries mentioned to attribute this art to various regions and races is the leading factor giving strength to this mistaken view. For example, doubts and questions have always been put forth as to whether the glass articles made in Seljuk or Artuk countries were their own or else whether they belonged nearby Syrian or Byzantine artisans, even though it is now known that the glass mosaics of the Artuks were local products, and Seljuk glass articles, some of which are with human figures, are also the work of the Seljuks. A short time ago, one f the experts of the British Museum was able to establish that a glass article with such a human figure was the work of the Seljuks.

Similarly, it is also a fact that the colored glass windows called Rovzen which were used by the Seljuks in their major buildings more for purposes of decoration than of lighting were not copies of Byzantine stained glass but were made with an entirely different technique and style. The oil lamp globes, chandeliers and the like which were used in inerior lighting are also implementations and treatments which are unique to them. Nevertheless the limited number of examples and amount f information belonging to these periods is the most significant factor preventing these subjects from being adequately known or learned.

The Period of the Ottoman Empire

The Sixteenth Century in particular was the golden age of Turkish glass-making, as it was for Europe as well. "The various glass articles made throughout the centuries among the Ottomans in their domestic workshops are valuable examples indicating what the Turkish workman could put forth with his intelligence and skill in the matter of meeting material needs, and at the same time indicating with what delicate taste he worked in order to satisfy the feeling for the fine arts in his soul. The oil lamps, tulip vases, flower vases, rosewater flasks, spouts, bowls made of plain or colored glass or of crystal, carafes, cooling vessels, flasks, glasses, cups and sugar bowls, mirrors, glass decorations, bottles for perfumes, drugs, and illumination, and in addition the bombshells for use in the army, the lanterns for the fleet, the lamp glasses, and the various glass articles and lancet windows made of colored glass in old structures will be sufficient to prove this statement."

These lines are taken from a brochure from a Turkish Glass Exhibition held in Ankara in 1947.

It is a fact that glass articles in the Ottoman period as well bear the "is it domestic or an import" doubts we mentioned above. The reason for this is that glass articles manufactured in Europe were also made according to Turkish taste, and that difficulty is experienced in distinguishing them from domestic products. Thus it is that Verre Turc (Turkish Glass) in the Ottoman period had two meanings; the first being glass articles made by the Turks, the second being glass articles made in European countries according to Turkish tastes. It should not be forgotten that the roots and history of glass-making have not been determined precisely. In addition the lack of light thrown on or research into the history of glass-making is one not peculiar solely to Turkey.

Reference: Antika; The Turkish Journal of Collectable Art, April 1985,

Issue: 1 By Fuat Bayramoglu

Glass-making during the Ottoman Period

As it was in other branches of industry, the influence of the excellent and thorough organisation of the glass industry and its trade was great in the development of glassmaking in Turkey. In that period, the manufacture and sale of glass was subjected to serious regulation and supervision; nor were the continued aid and protection of the State lacking. This organisation and the social, economic and similar measures and regulations have an interesting past from the standpoint of Ottoman history.

Until the end of the Eighteenth Century, every class and group of artisans created organisations known as "Semi-religious Youth Movements" or "Trade or Handicraft Guilds". At the beginning of the Eighteenth Century, these were replaced by newly formed Tradesmen's Guilds. Commerce and the arts were limited by trade monopolies and changes of every type were made possible with the permission of the State. The glassmakers and bottle-makers possessed functionaries known as masters, wardens, administrators, sergeants, foremen, and prayer leaders, as well as workshop owners who were masters. These duties were given to persons who had served as apprentices in the

palace organisation known as the Sultan's Private Domain and had left. Their salaries were originally paid by the Guild Fund, but later by the State. The Administrator was elected by the tradesmen and carried out all the affairs of the class. When the Guilds were formed, this office was abolished and given to the Wardens. The Trade Wardenship was an official duty representing the government in the guild. The power of his appointment and dismissal belonged to the government. Still, the Warden was a member who was elected by the trade and who acted on behalf of the trade. The person elected was presented to the Governor of Istanbul and depending upon the results of his investigation, he would be appointed by the government again with the Governr's approval. Sometimes the government would appoint a person from outside whom it considered suitable and the people leaving the Sultan's Private Domain and apprentices were included in this group. The Foremen and Prayer Leaders were elected by the trade. The title of "foreman" was given in the second half of the Eighteenth Century to the former "trade sergeant". They were a sort of officers of the peace. After the establishment of the guilds, they were second in importance after the wardens. The Prayer Leaders were not obliged to come from the trade, but were chosen as an upright person. He was paid an annual fee from the guild fund. A number of trade classes maintained their prayer leaders even in the period of guilds.

Those dealing in the glass business were separately organised and regularised as makers of glass, bottles, crystal, and mirrors. In addition to these, there existed the women's ornaments in the form of a sort of false glass jewelry known as the "Mercan Market", jewelers, and the class of glass dealers and glaziers. These last two classes were under the jurisdiction of the Chief Architect. Among the 45 classes of artisan in Topkapi Palace, there also existed glassmakers known as camgeren, chief of which was the Head Glassmaker. The glaziers fraternity, included among the various branches of the Istanbul Bostanci Fraternity was responsible for installing window glass in the palace and in the buildings and facilities associated with the palace.

Necessary arrangements were considered for the training of those dealing in glass-making, the protection of their old-age and retirement rights, and their insurance, and foundations were established. Included in the assistance they were given by the State were measures taken so that glass-makers would not encounter shortages in finding wood, as well as such principles as the sale of broken bottles and glass (known as "stock") which was melted down and re-used in the manufacture of bottles solely to owners of glass foundries, prevention of profiteering by Jews who collected such broken glass, and the prohibition of its exportation to foreign countries.

The glass which was manufactured was of three types; plain glass, coloured glass, and crystal. Glass and bottles which were not made according to specific dimensions and weights, fraudulent and low-grade glass would be broken by the Master and craftsman who produced them would be punished. Just as the names, qualities, and weights of glass articles were determined, so too were their trading prices. A current price register belonging to the period of Sultan Ibrahim (1640-1648) and dated 1050 A.H. (1640 A.D.) contains a long price list for domestic and imported glass, bottles, mirrors, and similar articles.

Luxury Products; lamps, oil lamps, tall thin tulip vases, flower vases, etc.

Useful Products: These were made for use by the military or for daily use, and included coloured or plain glass ship's lanterns, dome windows for Turkish baths, shell glass windows, and glass grenades.

Ornamented Glass and Pane Glass: Various pane glass for the windows of old buildings, ornamented glasses, coloured glass for lancet windows are included in this category. Products of this type were known among the Ottoman Turks as ornamental glass and were made with a technique totally different from European stained glass work, being very decorative, and rich in quality.

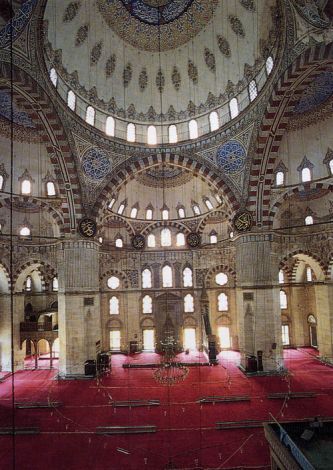

Lancet windows were located in a second row above the windows which permitted one to look outside. Every lancet window consisted of two parts; an inner window and an outer window. The inner windows were indeed true works of art. The coloured glass windows made for Suleymaniye Mosque by the artisan known as Ibrahim the Drunkard in the reign of Suleyman the Magnificent (1520-1566) are quite famous. The name of this master must remind us of these lines by the Magnificent At the feast of connoisseurs I styled the sky marvellous/The lamps of the mosque I made into windows for the tavern.

Reference: Antika; The Turkish Journal of Collectable Art, May 1985,

Issue: 2 By Fuat Bayramoglu

Glass-making among the Turks

When the Turks captured Istanbul (1453), the city had already lost in every respect its former sparkle and greatness. The huge empire had contracted to the point where in fact in included nothing more than the city and its surroundings, and it struggled to maintain its ancient repute. When the Turks took the city it once again reassumed the aspect of an imperial center, constituting as well an active focal point for the glass industry. In fact Byzantium possessed a significant past and tradition from the standpoint of the art of glass and its products. When the glass factories passed into the hands of the Turks, they were kneaded with the Turks own experience and store of knowledge and more meaningful and valuable products began to appear. When the craftsmen and workers making glass became Turkish, the delicate taste of the Turks of the period, their creativity and their skills gained even greater significance. When we look at the names of the glaziers who worked at the construction of Suleymaniye Mosque, a group of 17 people appears before us. The fact that of these seventeen individuals only one was a non-Muslim is a perfect example of he degree to which the Turks placed importance on the art of glass-making in this period.

The glass-making centers in Istanbul concentrated in the areas of Egrikapi and the Palace of Hebdoman. Around the Imperial Powder Mill in Bakirkoy there were large grinding wheels and mortars operated by animal power. In addition there were burnishers, a glass foundry and a saltpetre boiler and furnaces. A traveller who visited Istanbul in 1544 by the name of Pierro Gyllii wrote that a glass factory belonging to the Padishah existed inside the palace. From the notes of the same traveller we learn that glaziers were to be found in the mosque called "Glaziers Mosque" in Aksaray.

Eyup, in the area of Ayvansaray, possessed factories making glass and lanterns. Mustafa III. (1757-1774) collected the glass-makers from all these widely scattered locations into the site of Hebdomon Palace.

The Istanbul region possessed major sources providing the raw materials required for glass-making. The fine white sand most suitable for making glass was dredged out of Kumbogaz, "just half a day's journey" from Yedikule.

Documents attesting to the opening of glass factories outside Istanbul, and to the performance of this craft in these places are important from the standpoint of showing the degree of importance afforded to this subject. Examination of the miniatures reflecting the "Procession at the Prince's Circumcision Festivities", one of the most important events of the world of that day, should be sufficient to give an idea on this subject.

Beykoz Glassware

The Nineteenth Century for the Ottomans may be referred to as the final brilliant period in which beautiful works were brought forth and a few of their enterprises and successes took shape. Were we to list a few of the important undertakings, one would first have to make mention of "Beykoz Glassware".

A glass factory was established in the reign of Selim III. (1789-1808) by an artisan by the name of Mehmet Dede, a Mevlevi dervish near the town of Beykoz on the Anatolian shore of the Straits of Istanbul. This was followed by the Glass and Crystal Factory established in the same region at Incir Koyu in Cubuklu by a governor by the name of Mustafa Nuri Pa_a (1798-1878). In 1848 this factory was purchased by Sultan Abdulmecit (1839-1861) and expanded. It was here that the famous "Cesmibulbul" (meaning "Eyes of the Nightingale", given to a precious kind of Turkish glassware with spiral decorations, and opaline glassware was manufactured. This work achieved a perfection which was to be favourably compared with the products of Bohemia and Venice from the standpoints of beauty and quality, and it became famous throughout the empire and in a number of neighbouring countries. The fact that these pieces have appeared in Tunisia and India gives an idea of degree of their prevalence. Taking the name of the district of Istanbul in which these glass articles were manufactured. It became common to call them "Beykoz glassware", or "Beykoz" for short.

Beykoz work is quite varied. In addition to plain, coloured and colourless glass, there also exist nieces which are of coloured and milk-white opaline. In particular the fact than in that period opaline glassware was popular in Europe was cause for vessels, bottles, and similar articles of this type of glass to be made everywhere. In addition it led to copying of Turkish products for the Turkish market. In fact, today it is quite difficult to distinguish between Beykoz articles made in Turkey and those made abroad, and is a matter for an expert.

One of the final enterprises in this field during the Ottoman period was the glass factory established in Istanbul, again in the same district at Pasabahce, under the name of "Fabrica Vetrami di Modiano Constantinopoli" by an Italian Jew in 1899. This company, which by 1902 had grown to a capacity of 500 workmen, in the same year was forced to close its doors. The major reason for this was European competition. The factories which the State and private individuals wished to keep alive for many years struggled to hold on, but were forced to close down. Because of the Capitulations on goods coming from abroad, customs duties and restrictions were not applied, and this lack of protection led to the crushing of domestic manufacturing and its disappearance. Similarly, the First World World Was (1914-1918) resulted in the destruction of everything.

It was only during the period of the Turkish Republic that this situation changed. A factory established in Pa_abahce in 1935 through the efforts of a national bank, took advantage of old glass molds and commenced operations. The factory grew day by day and reached a new and brilliant stage. With the importation in 1937 of the first automatic machinery, the factory grew even stronger. This company, reorganised under the name of "Turkiye Sise ve Cam Fabrikalari" today carries out production through its factories as a major holding company.

In the historical development of glass manufacturing in the world, both handicraft and automatic production have for years existed side by side and developed, and it was the same in Turkey. We see that thirteen years ago (1972), there were seventy organisations engaged in activity in the glass-making industry, all of which were private companies, and with the exception of one or two mostly hand-blown work was performed. This is undoubtedly a cause for joy.

With its present level, the glass-making industry in Turkey today is capable of meeting all the demands of the country, whether it be in terms of quantity or of quality. In addition, even with a number of exceptions, it is on the average at the same level as more developed countries in every field, whether it be the technology employed or the means of production.

Glass products of every type are exported primarily to the United States, West Germany, Italy, the countries of the Near East and others as well. This exportation shows development every year.

Silicate sand, limestone, and since 1975-soda, the raw materials for glass are all obtained domestically.

Source: Antika; The Turkish Journal of Collectable Art, June 1985, Issue: 3

By Fuat Bayramoglu